If you’re into carpentry, fabrication, or renovation projects, you know how essential a chop saw can be. You can use them for cutting wood or other materials, in different angles and widths. In this article we compare various chop saw types and features from a safety and function standpoint.

Main Chop Saw Components

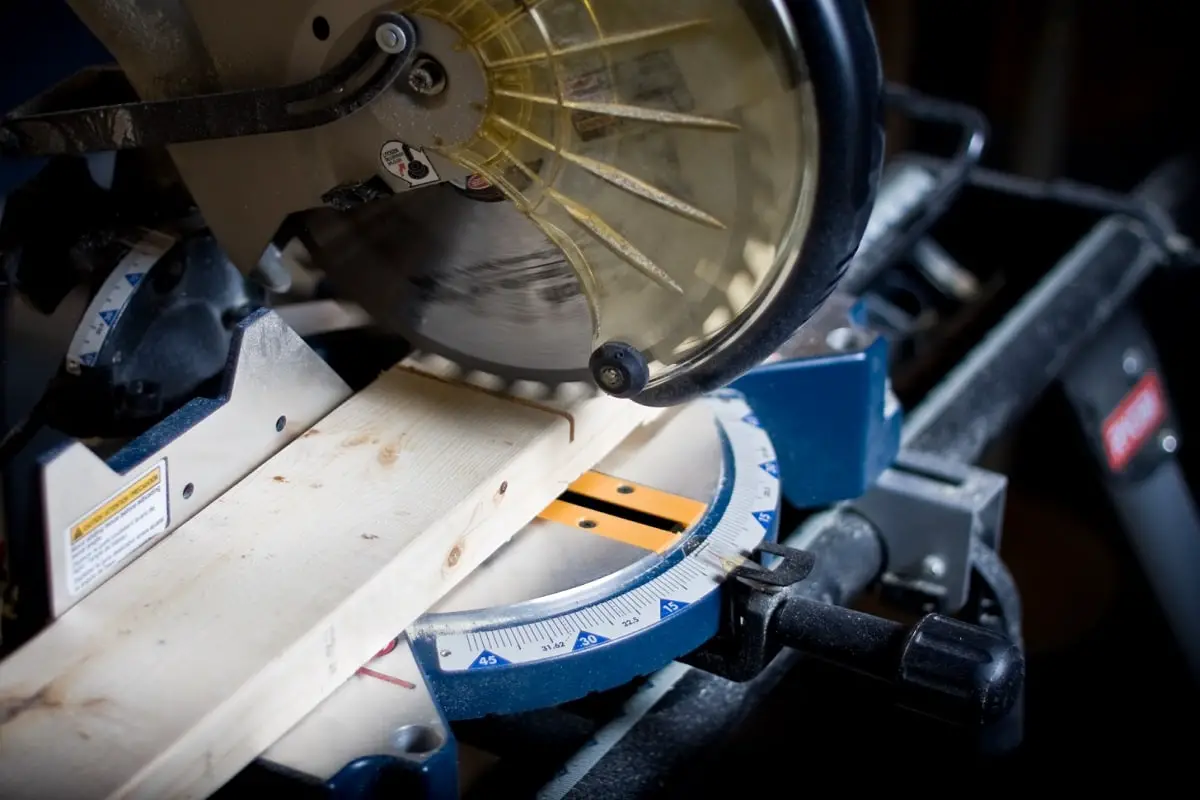

A chop saw features a stationary table or frame with a hinged arm fixed upon it. A high speed circular blade with an abrasive surface is attached to this arm and the motor with it.

Chop saws have a handle that moves the blade toward the material you’re cutting

The base can rotate in one or more dimensions, allowing you to make square and angled cuts.

Chop Saw Features & Variations

Standard Chop Saws

These chop saws are designed to cut only downwards, thus limiting the cutting to one plane. You can’t move the arm horizontally.

Compound Chop Saws

In this type of chop saw, you have the option of tilting the blade in one additional direction from its original position, so you can cut material in two planes.

Dual-Compound Chop Saws

Dual-compound chop saws are similar to compound chop saws, with the difference being that you can move the blade either left or right. This feature provides you more versatility in terms of angles and allows you to make bevel cuts without having to move the material.

Sliding-Compound Chop Saws

This type of chop saw encompasses all of the features above. However, it provides you with more utility by allowing you to move the blade back and forth, as well as left and right. So, you can cut large pieces of wood easily with these.

Chop Saw Laser

Many chop saws in the market come with laser beams attached to them. These show you the blade’s path across the material, thus helping you achieve a cleaner and more accurate cut.

There’s still a margin of error even when you use a laser beam to mark the material because the laser isn’t attached to the blade or its arm. So, there’s always a slight inaccuracy. Also, lasers can be difficult to see properly in bright light, which can render them ineffective.

Cordless Chop Saw

As the name suggests, a cordless chop saw doesn’t have a power cord with it, which means a battery pack powers it. This feature provides you with more accessibility and portability and makes it easy to use where you don’t have access to a power outlet.

However, a cordless chop saw may not provide you with the same speed and power that a corded chop saw would. Plus, you always have the risk of the battery running out while you’re using it. To avoid work downtime you will need to have several charged batteries on hand.

Chop Saw and Table Saw in One

You can combine a chop saw and table saw into one. Simply put, you can build a workbench on which you can mount both the table saw and chop saw. A table saw has a fixed circular blade without any movement, and you guide the material towards it.

Having both the chop saw and table saw in one place will allow you to work on larger pieces of wood and also complete longer or more detailed projects on time.

Chop Saw and Stand

Although a chop saw doesn’t need a stand to function properly, it adds a level of stability and convenience to your work environment. A stand elevates the chop saw, meaning you don’t have to bend over and put pressure on your back. Your productivity and accuracy will improve, especially on long work days.

Industrial Chop Saw

This type of chop saw is much larger than typical home or contractor chop saws, and they have a larger motor that delivers higher RPM. They are used for a wide range of manufacturing purposes, such as metal cutting, lumber cutting, etc.

Wood Chop Saw

Although there isn’t much of a distinction between chop saws that can cut different materials, the major difference is in the type of blade, which helps you cut through the material. A wood chop saw blade is often made of carbon steel or high-speed steel and has a blade with 40 to 80 teeth.

Metal Chop Saw

When it comes to cutting metals, you’ll need a different type of blade. For this purpose, you can use carbide-tipped blades, diamond blades, or abrasive discs. However, make sure that your chop saw has enough RPM to properly cut through any metal. Otherwise, it can result in rough edges or even cause your tool to malfunction.

Abrasive Chop Saw

You can use abrasive chop saws for hard-to-cut and tough materials, such as most metals, tiles, concrete, and many others. They specially come with a thinner abrasive disc with uneven edges that help cut through these materials cleanly.

Chop Saw vs. Band Saw

A band saw features a long and toothed blade instead of a circular one, and it’s installed vertically between two or more wheels. Band saws are great for long cuts, scroll cuts, and easy cutting of thicker pieces of wood. The main difference between them is that the band saw’s blades last much longer, thus being more cost-effective. In terms of portability, the chop saw is more suitable.

Chop Saw vs. Table Saw

Since we’ve mentioned table saws in the previous section, so you have an idea about how they work. The basic difference between the two is that with chop saws, you guide the blade towards the material, whereas with table saws, you guide the material towards the blade. The former allows you more maneuverability, as you’re in more control over the blade.

Chop Saw vs. Circular Saw

Circular saws are handheld power saws with a similar blade to chop saws, and you have to guide it to wood in a similar fashion to them. However, you need to have a steady hand and more control over the power saw. Otherwise, there are greater chances of error. However, circular saws are more affordable and portable.

Chop Saw vs. Miter Saw

You must be surprised by this since we’ve been told that miter saw is just another name for chop saw. However, there are certain differences between the two. Chop saws are much larger and more powerful than miter saws, whereas miter saws provide more versatility. Miter saws allow you to perform angled, beveled, and compound cuts and rotate them left and right.

Chop Saw Safety Rules

As is the case with every power saw out there, you should always follow certain safety rules and regulations to ensure a safe and proper operation of chop saws. Some of these tips are:

- Never turn the saw on when the blade is touching the surface or any material.

- Make sure to wear all safety gear, such as goggles, face shields, masks, cut-resistant work gloves.

- Ensure that there are no scraps on the blade when you turn it on.

- Allow the blade to reach its full RPM before you start cutting any material.

- Choose the appropriate blade for every material.

While all power saws come in handy for various applications, a chop saw is one of the safest and most versatile options out there. You can use them for nearly any and every woodworking, fabrication, or renovation project that you undertake.

When it comes to choosing a chop saw, make sure to examine all of its features to have an idea of its usefulness. Otherwise, you may end up with a power saw that doesn’t do the job it’s intended for, and you’ll have to spend money on another chop saw.