In this article we describe the most common materials box cutters are capable of cutting. We also show you ones you should avoid.

Cardboard of Course!

The box cutter was designed to, well, cut cardboard! A box cutter with a new sharp blade can cut through basically any type of cardboard or paper board. The tricky part of cutting cardboard is the direction and angle you cut it from.

The easiest way to cut a cardboard box is by cutting with the grain or natural folds in the material. Between the two outer layers is a folded layer of thick paper glued to them. Ideally, you want to get your box cutter blade in a valley in the inner layer. The blade will easily follow this valley and cut the cardboard with minimal effort. You can often cut right through all the layers at once this way.

Cutting against the natural grain or folds of cardboard makes the job much harder. Instead of following a natural fold, the blade will tend to wander and hang up. Cutting repeatedly through the inner folds against their direction causes the fibers to wrap around the blade and slow you down. When cutting against the grain, it’s often useful to tip the box cutter down into a shallower angle and drag it quickly across the surface. You will probably need to follow your cut line again two or three times to slice all the way through.

Wet cardboard seems to present a big problem for a box cutter. Rather than slicing cleanly through, the wet fibers either fall apart or wrap around the blade, which causes ripping.

Other factors include how much foreign material is included in the area of the cardboard you’re cutting. Packing tape, straps, glue, plastic coating, even large staples might get in the way of your box cutter blade.

Cutting Paper With a Box Cutter

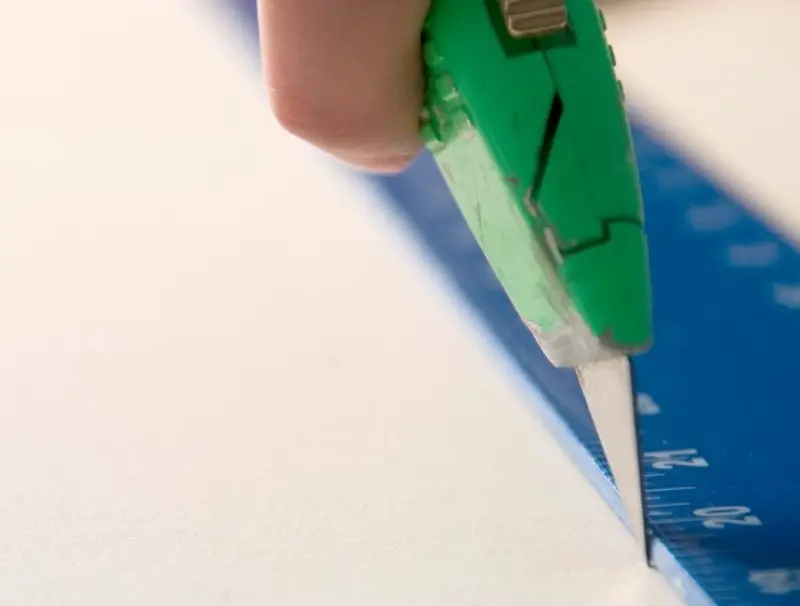

Most box cutters can handle paper without any issue. Some thick paper or paper board with high fiber content may want to wrap around the blade. This can cause rips and tears, rather than slicing cleanly. To counter this be sure to use a sharp blade, pull the blade along at a shallow angle using a metal straight edge and go slowly.

Recommended Box Cutters

DIYSELF 2Pack Utility Knife Box Cutter Retractable Blade Heavy Duty

Slice 10515 Mini Box Cutter, Ceramic Blade Locks Into Position, Right or Left Handed Mini Cutter

WORKPRO Folding Utility Knife Set Quick Change Blade, Back-lock Mechanism

Cutting Wood With a Box Cutter

Similar to plastic, a box cutter can usually slice through wood up to 1/8 inch thick. You can go thicker with some soft woods. Box cutters are not shaped to shave or carve wood, so you’re pretty much limited to slicing or cutting at a downward angle on a flat surface.

Soft Woods

- Balsa. This wood is very soft and can be cut easily with a sharp box cutter. Straight lines work best.

- Pine. Pine is a fairly soft wood, but box cutters can have trouble with the grain. You may need to make a few passes to get through it.

- Fir. Fir is soft wood like pine, and box cutters can cut through it OK. You will want to cut with the grain and avoid knots.

- Redwood. Redwood is also soft wood. Box cutters have no issue cutting through thin redwood strips or veneer.

Hard Woods

It’s best to use a metal straight edge with a box cutter when cutting hard wood. Most hard wood you might cut with a knife is thin strips or veneer used for cabinets, canoes and fine woodwork. Be prepared to replace your blade more frequently.

- Oak. This is a tough one! Oak is very hard and will quickly dull your box cutter blade. If you must cut it, go slowly, scoring the wood repeatedly to get through it.

- Maple. Maple is a harder wood, but box cutters can still handle it. Just be sure to use a sharp blade and use multiple passes to get through cleanly.

- Cherry. Cherry is a beautiful wood, but box cutters have trouble with it. Be sure to use a sharp blade and make multiple slices.

- Mahogany. Mahogany is very hard. A box cutter will only work on small, thin strips.

- Teak. Teak is also very hard and dense. A box cutter should be used only on thin strips.

Can You Whittle Wood With a Box Cutter?

Yes, you can whittle wood or other soft materials with a box cutter. However, the blade shape, length and angle are not really suited to whittling. Box cutters are designed to slice vertically in a straight line, not sweep across a piece of wood taking thin shavings off. The blade will tend to bite in and hang up, making your whittling project less enjoyable and potentially a bit dangerous.

Can Box Cutters Cut Plastic?

Soft Plastics

Box cutters easily cut through softer plastics like those used in food packaging, shrink wrap and hanging product packages. Soft plastics include plastic materials like:

- Plastic Shrink Packaging: Box cutters easily slice through shrink wrap and thicker clear shrink packaging used for hanging display products.

- Polypropylene (PP). Examples include reusable water bottles, yogurt containers, ketchup and mustard bottles.

- Polyethylene terephthalate (PET or PETE). Examples include soda bottles, peanut butter jars, cooking oil bottles.

- High-density polyethylene (HDPE). Examples include milk jugs, laundry detergent bottles.

- Low-density Polyethene (LDPE). Examples include wire insulation, flexible container lids & bottle tops, condiment bottles.

- Polyethylene Terephthalate (PET). PET is clear plastic used for water bottles, soft drink bottles, food packaging, drop cloths, carpet, rope, clothing, construction materials, etc. When spun into fibers it is called polyester. Box cutters will easily cut through thin PET up to 1/8 inch, and will score thicker PET without any effort.

- Polyethylene Terephthalate Glycol (PETG). PETG plastic is used for impact-resistant glazing, product displays, signs, containers and 3D printing. It is easily formable and melts at low temperatures.

- Nylon (PA or Polyamide). This is a strong and stiff plastic used in applications like fishing line, weed cutting line, electrical fittings, carpet, small gears, bushings and car parts. It can be reinforced with glass fibers. Box cutters will cut through thin nylon easily. You can also cut thicker material if you make multiple slices.

- Silicone. These rubber-like plastics are soft and malleable, used to seal joints, reduce vibration and attach parts together. Cutting silicone is generally no problem for box cutters.

Hard Plastics

Box cutters can make clean cuts through many hard plastics up to 1/8 inch. But they will not cut through thicker material or hard plastics with low-friction, impact resistance or heat resistance properties. To cut hard plastic you will need a heavier blade, and it must be very sharp. Hard plastics include:

- Acetal (POM or Polyoxymethylene). This plastic is used in precision gears, wear strips, valves and other wear-resistant applications. It is friction-resistant and stiff, making it difficult for box cutters to cut through.

- Polycarbonate (PC). This shatter-resistant plastic is used for safety goggles, food storage containers and water bottles. Box cutters will cut through thin polycarbonate, but not if it’s more than 1/8 inch.

- ABS (Acrylonitrile Butadiene Styrene). This black plastic is used for car fenders, computer keyboards and toys. It’s very tough and flexible and box cutters will not easily cut through it.

- PVC (Polyvinyl Chloride). This is white, grey or clear plastic used for pipes, siding and shower curtains. It’s fairly soft (for a “hard” plastic) and box cutters will cut through it pretty easily. You can shave slices off of thicker pieces if you need to.

- Phenolic. Phenolic plastics are thermoset (heat molded) composite materials, usually with some cloth, fiber or glass reinforcement. Phenolic is used in circuit boards, Bakelite and structures like shelves and cabinets. Box cutters will not slice through it.

- Acrylic. This is the clear plastic used for aquariums and other see-through applications. Box cutters will score acrylic, but it is difficult to cut through it with any sort of knife because acrylic is hard and brittle. You are more likely to crack acrylic than cut through it with a box cutter.

- Polyimide. Polyimide is a heat-resistant plastic used in electrical applications. It’s often used to make the base for kitchen appliances like toaster ovens and slow cookers. Box cutters can be used to score polyimide, but it is difficult to cut through.

- Epoxy. Epoxy is a strong, hard, durable resin used in many industrial and commercial applications. It is very difficult to cut epoxy with any type of knife, including box cutters.

- High-Impact Polystyrene. This plastic is very flexible and durable. It is used for toys, TV and audio-visual equipment parts, automotive instrument panels, gas tanks, drinking cups and computer housings. You can cut through High-Impact Polystyrene with a box cutter if it is thin. However, you are more likely to end up scoring thicker material and will need a saw to do the job.

- Polyamide-Imide (PAI). PAI is an extremely strong and stiff plastic often used in high-temperature industrial and automotive parts where its low coefficient of thermal expansion (CTE) maintains its dimensions. Box cutters cannot cut PAI plastics.

- Polybutylene Terephthalate (PBT). PBT is a strong, stiff thermoplastic polymer. It is normally used as an insulator for electrical products, TV accessories, switches, sockets and other electrical and automotive applications. Box cutters cannot cut through PBT plastics but can score them.

- Polyether Ether Ketone (PEEK). PEEK is a dense, stiff and abrasion-resistant plastic used in high-temperature precision environments such as aerospace, automotive and industrial. Box cutters will not cut through PEEK plastics.

Can a Box Cutter Cut Metal?

Yes. A box cutter will cut thin, soft metal. However the cutting blade will become dull quickly, so be prepared to change blades often.

- Aluminum. Aluminum is a fairly soft metal. Box cutters can easily cut through thin aluminum, such as aluminum foil, aluminum tape, soft drink cans and aluminum tape. Box cutters will score thicker aluminum, as well.

- Zinc. Zinc is a soft metal that box cutters can slice through quite easily up to 1/8 inch thick.

- Copper. Copper is a pretty soft, malleable metal. Box cutters can slice through very thin copper, such as copper tape and foil. A box cutter can only score thicker copper.

- Lead. Lead is a soft metal, and box cutters can definitely cut through it.

- Brass. Brass is a strong, stiff metal. It cannot be cut with box cutters.

- Tin. Tin is similar to aluminum in it cut resistance. A box cutter can poke a hole in a tin can, but will have trouble cutting it. Not recommended.

- Steel. Box cutters cannot cut through steel, even thin steel.

Cutting Fabric With a Box Cutter

Box cutters can generally cut through fabric with minimal effort. However, it’s important to use a sharp blade and cut downward through the fabric on a hard cutting surface. Otherwise the fabric fibers will bunch up around the blade and interfere with the cut.

- Cotton. A box cutter can slice through a layer or two of cotton fabric without any issue.

- Linen. Linen is a bit stronger than cotton. Box cutters can easily slice through linen fabrics.

- Wool. Wool is a strong fabric with heavy fibers. Box cutters can slice through densely knit, thin wool, but not fluffy or loosely knit wool.

- Silk. Silk is generally thin fabric with densely woven fibers. Box cutters can render silk easily.

- Polyester. Like polyester plastics discussed above, polyester fabrics, ribbons and tape can be easily sliced with a box cutter.

- Fiberglass Cloth & Mat. The glass fibers in fiberglass cloth and mat are very strong and move around freely. Box cutters cannot cut through it cleanly — you need sharp scissors.

- Carbon Fiber. Carbon fiber cloth is highly cut-resistant and the fibers move around a lot. Box cutters cannot cut through carbon fiber.

- Kevlar. Kevlar fibers are exceptionally resistant to cutting, stretching and abrasion. Box cutters cannot cut through kevlar fabric.

What Other Materials Can Box Cutters Cut Through?

Your Skin! The obvious danger with box cutters is you slicing your own skin. Of all the materials discussed above, skin is the easiest to cut. So wear some thick leather gloves or keep your other hand and body parts away from the object you’re cutting.

Wallboard. The interior wallboard used in houses is easily scored with a box cutter, then snapped in two along the score line. Wallboard has two outer layers of paper sandwiching a gypsum or plaster-like interior. By cutting the outer paper that holds the board together, pieces can be easily snapped off.

Thin Fiberboard & Pegboard. Thin wood fiber pressed board can be cut with a box cutter similar to interior wallboard. Just score a deep cut line using a straight edge and box cutter, and snap the board in two pieces along the line.

Window & Door Screens. Screens are made of coated fiberglass strands or thin aluminum wire. A box cutter can zip right through a fiberglass screen. Aluminum wire screens are tougher — a box cutter will cut through but it will take longer and dull the blade.

Tape. Masking tape. Duct tape. Clear tape. Strapping tape. PVC tape. Electrical tape. All can be easily cut to length with a box cutter.

Your Dinner Steak. If you forgot your steak knife just go for it with your box cutter!

So there you have it! Box cutters can cut through a wide variety of materials, but some will be more difficult than others. Always remember to follow safety precautions by cutting in a controlled way, wearing thick leather gloves and keeping your body parts out of the way of your box cutter blade.