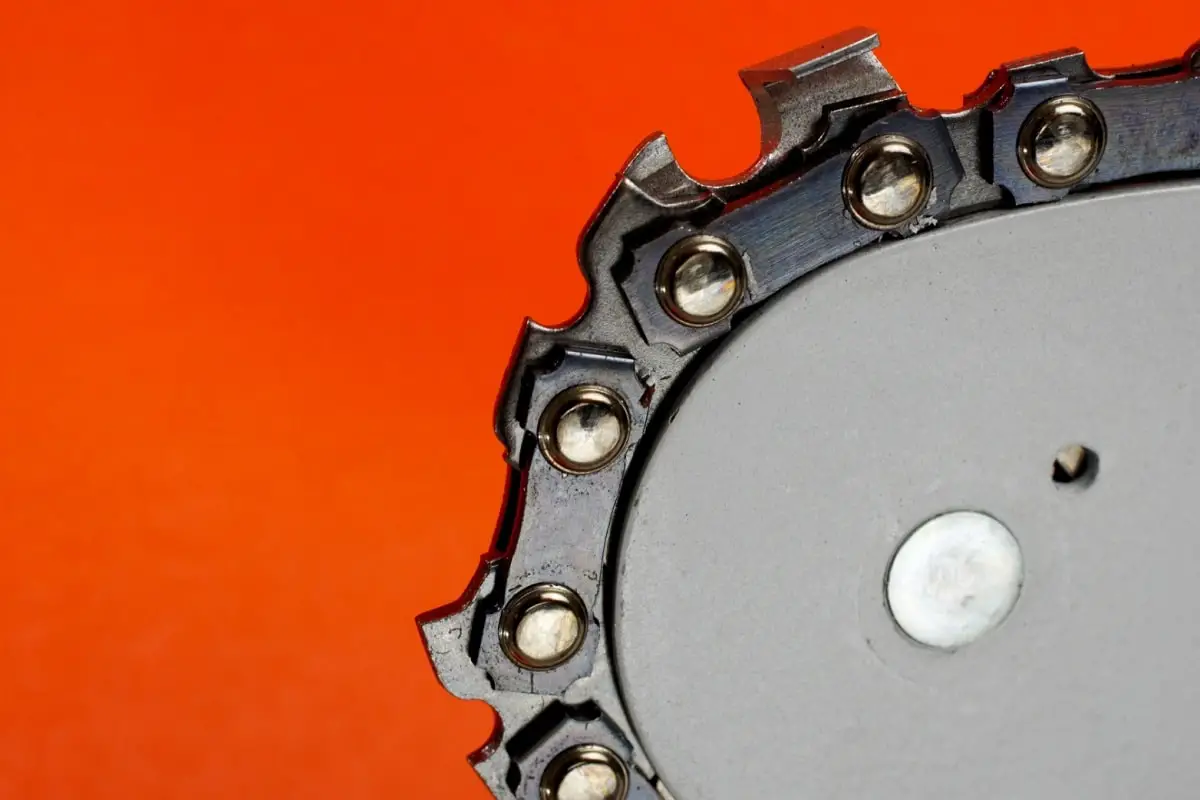

Chainsaw chains come in a variety of types and sizes. The one best for you depends on what kind of materials you need to cut. This post covers the types of chainsaw chains you might need for your next cutting jobs.

Types of Chainsaw Chains

Many people are surprised to find out that chainsaws have a wide variety of chain types they can use.

Chainsaw chains can be broken up into many types, with each best for certain cutting tasks. These include:

- Chisel

- Semi-chisel

- Full-chisel

- Anti-kickback

- Low kickback

- Regular (skip tooth)

- Aggressive (full skip)

Further, there are additional chainsaw types, including:

- Self-sharpening chains

- Low-vibration chains

- Self-lubricating chains

Specialty Chainsaw Chains

Specialty chainsaw chains also exist, and include:

- Ripping

- Narrow kerf

- Low profile

- Carbide tipped

Full Skip Chainsaw Chains

Full skip chainsaw chains have about 2/3 the number of cutting links as a standard chain. This is so the chainsaw does not have to exert as much energy. These are also faster to sharpen because they have less cutters.

Full skip chains are suitable for low or underpowered chainsaws with longer bars. They are also good for cutting green wood.

Full skip and semi-skip can also come with full chisel and semi-chisel chains.

Semi-Skip Chainsaw Chains

Semi-skip chains have more cutting links than full skip chains. Semi-skip chains usually have square shaped cutters. Like full skip, semi-skip causes less drag and draws less power from the motor. These chains can make fast cuts and are good for low-powered saws with very long bars.

Low Profile Chainsaw Chains

Low profile chainsaw chains have the advantage of being lower weight than regular chains. This places less strain on the motor. These are best for low-powered saws, especially electric saws.

Low profile chains are made in 3/8″ pitch and .050″ gauge and only fit bars that are made for low profile chains. A low profile chain cannot fit a chainsaw bar made for more than 72 drive links.

Narrow Kerf Chainsaw Chains

Narrow kerf chainsaw chains cut thinner than standard chains, making them ideal for electric chainsaws. They can even fit a full-size chain on a low-horsepower chainsaw. However, a bar has to specifically fit narrow kerf chains to work.

Narrow kerf chains can also be low profile, meaning they are both light and high speed.

Ripping Chainsaw Chains

Ripping chainsaw chains are made for cutting logs into smooth planks of wood. They make finer cuts than standard chains, and are also less aggressive. Ripping chainsaw chains are also more expensive than regular chains.

Ripping chains cut at a lower angle than standard chains, 10 degrees instead of 30 degrees. They are best used to cut along the wood’s grain and not against it.

Ripping chains are ideal for sawmills or craftsman looking to make finely cut planks of wood.

Types Of Chainsaw Chain Cutting Links

There is more to know about chainsaw chains that just the type of chain. Each chain can also have different types of cutters. This issue stands out when full-chisel and semi-chisel chains come into the picture.

Full Chisel Chainsaw Chains

Full chisel chainsaw chains have sharp, square pointed cutters which are very good at cutting aggressively and quickly through wood. These are very popular with professional chainsaw operators.

Semi-Chisel Chainsaw Chains

Semi-chisel chainsaw chains only have rounded cutting edges meant to dull more slowly. These are able to withstand rough conditions, making them ideal for homeowners and non-professional cutting.

Both full chisel and semi-chisel also come with full skip and semi-skip chains.

Types Of Chainsaw Chain Cutter Tips

There are also different types of chainsaw cutter tips, each made of different materials. These determine how well and fast the chain cuts. These materials include:

- Carbide

- Chrome

- Diamond

Cutting tips dipped in chrome helps to keep them sharp, not just for a nice shine.

Carbide tipped chains are not as affected by heat as chrome tipped chains, and last longer. This makes them better for cutting dense and large wood planks. They are also great for emergency situations where crews need to cut through walls, icy or water logged wood.

The downside to carbide tipped chains, is that they are expensive to both purchase and sharpen.

Diamond is one of the hardest materials known to man, so diamond tipped chainsaw chains adds a considerable ammount of strength. These chains can cut concrete and rocks and will only work on chainsaws and bars that are made for them.

Low-Kickback Chainsaw Chains

Both Low-kickback and Anti-kickback chainsaw chains are designed to reduce the chances the chainsaw will kickback and cause injury.

Kickback is when the chainsaw bar hits a hard or jagged material and jolts back up and towards the operator. This can cause serious facial and upper torso injuries. The “kickback danger zone” is the area at the top portion of the end of the chainsaw chain and bar.

A chainsaw that does not have anti-kickback ability should only be used by a trained professional.

Low-kick back chains have narrow kerfs, or a smaller width of material that is removed by the chain. This makes them require less power from the motor, but also causes the cutting to take longer.

Regular (Skip-Tooth) Chainsaw Chains

Skip-tooth chains have a skipped tooth, meaning there is one extra open space (link) between cutting teeth. This causes less resistance to the chain as it cuts. Skip-tooth chains can cut faster and make more rugged cuts.

Aggressive (Full-Skip) Chainsaw Chains

Full-skip chainsaw chains have two extra open spaces (links) between cutting teeth. These are mostly used with long guide bars and make aggressive cuts. These are made for professionals to use, and most homeowners will never need one.

Self-Lubricating Chainsaw Chains

Self-lubricating chains are designed to keep lubrication on the chain through grooves or holes in the cutting teeth. Chains chains need a level of lubrication to move freely without too much friction.

Self-Sharpening Chainsaw Chains

Self-sharpening chainsaw chains are filed to stay sharp each time it passes around the guide bar. Self sharpening chains need can only be used on self-sharpening chainsaws.

These chains save the user time by not requiring manual or professional sharpening. Just running them around the bar for few seconds can keep the chain sharp. However, this means that the internal sharpening stone will eventually wear out and need replacing. The chain will also not last forever and has a limit as to how much sharpening it can take.

Low-Vibration Chainsaw Chains

Chainsaw chains have vibration ratings from standardized testing done by the manufacturer. Tool vibration can cause serious health risks over long periods of time, such as wrist and hand numbness and pain.

Manufacturers have created low-vibration chains to minimize user injury by adding a space between the chain and guidebar that acts as a buffer from vibration. Low vibration chains need a certain called length on the saw to fit.

Most homeowners will not need low-vibration chains if they only cut occassionallly.

Carbide Chainsaw Chains

A chainsaw user may choose to use a carbide chainsaw chain over a regular chain. There are several reasons why carbide chains may be preferreable, including:

- They are stronger

- They last longer

- They are safer

Carbide tipped chains are made of hard carbide, silver solder, and specially designed teeth. These chains designed for difficult cutting jobs, such as demolition work or in rescue operations. Carbide chains are also good for cutting wood, and may last 5-10 longer than regular metal chains.

One big problem with carbide chainsaw chains is they are difficult to find a shop that will sharpen them. This leaves the user having to do it themselves.

Is It Worth Sharpening A Chainsaw Chain?

sharpening a chainsaw chain can be somewhat time consuming, so it is important to know if chainsaw chains are worth sharpening.

For the chainsaw users who use chainsaws regularly, chains will need to be replaced or re-sharpened periodically. Chains can dull for many reasons, whether it is because of heavy usage due to extensive woodcutting, or hitting rocks or other hard materials.

To make a chain last, it will eventually need to be sharpened. This can be at home or by a professional. Tools, such as hand files, a grinder, or a dremel can work for chain sharpening.

Whether it is worth doing it yourself, paying someone, or just replacing the chain is up to how much time and money you want to spend.

Having a regular 72 inch chainsaw chain sharpened professionally costs $10-20.

How Long Will A Chainsaw Chain Last?

Chainsaw chains can last a good length of time if they are sharpened. However, eventually they will need to be replaced.

A chainsaw chain will need to be replaced because it is dull, worn out, improperly tensioned or bent. Chains get sharpened by running them against a grinding wheel which trims burrs and burs off the links and re-establishes a pointed tip.

A regular chainsaw chain will last 5-10 years of semi-regular use. Professional chainsaw operators (forestry, tree trimmers) will have to replace their chains sooner. However, some chains can last decades if they are not used very often and do not break. Basically, there is no set lifespan for a chainsaw chain.

If a chain hits very hard objects, such as rocks, ice, or concrete, it could break and need replaceing.

Is 3/8 And .325 Chainsaw Chain The Same?

No, 3/8 (.375) and .325 are not the same when referring to chainsaw pitch sizes.

What Is The Difference Between .325 And 3/8 Chain?

Three eighths (3/8) can be converted to .375. Both .325 and .375 refer to pitches and the spacing between the rivets in the chain. This spacing is very important to type of chainsaw you are using and what you are cutting.

.325

.325 chians are good for small chainsaws because they require less energy to cut due to the smaller top cutter distance.

.375 (3/8)

3/8 chainsaw chains are better for larger chainsaws that provide more horsepower. These chains have large teeth and use more energy to operate. These chains are also easier to sharpen than .325 because the teeth are bigger.

You can switch from one to the other, but make sure the chainsaw’s sprocket and bar will match the new chain.

Will A 3/8 Chain Fit A .325 Bar?

The answer is Yes and No. Using the same guide bar for a .325 or a 3/8 chain is not recommended because the tension may be off.

However, the Oregon PowerMatch nose can be replaced on any Oregon PowerMatch bar. So, replacing the 3/8 with the .325 chain will work.

Or, the Duromatic guidebar with a solid nose can run a 3/8 or .325 chain. This requires two additional rim sprockets.

However, each chainsaw and bar has a specific chain size that runs best on it and these should not be switched out for a different sized chain. The result could be that the chainsaw does not operate effectively.

What Size File Does A .325 Chainsaw Chain Take?

A .325 pitch chain will use a 3/16″, 6/32″, or 4.8 mm file diameter size.

What Does 73 Mean On A Chainsaw Chain?

Each brand has its own unique way of identifying its chain sizes.

The three numbers that determine the size and cutting ability of a chainsaw chain are pitch, guage, and number of drive links. An additional number is the called length, which is the length of the bar from base to tip that can fit the chain. You must make sure your chainsaw is compatible with the numbers on the chainsaw chain to make sure it will run safely.

’73’ is the number the Oregon brand uses to identify the chain size for its chainsaws. You can find these numbers on each drive link on a new Oregon chainsaw chain.

Oregon uses standard numbers from 16 to 91. Each of these numbers only corresponds to the Oregon product number. ’73’ does not indicate the number of drive links, pitch, or guage.

Chainsaw Chain Measurements

You can usually find the chainsaw chain measurements on the individual drive links. Each manufacturer will have a different measurement id code. The stamped id will have the brand, and numbers on both the drive link and tooth link.

Some manufacturers will only have the number on the drive link and the brand name, and not a number on the tooth link.

Chainsaw Chain Sizes

Here are some examples of chainsaw chain sizes:

| Marking On Chain | Brand | Gauge | Pitch |

| A1 | Carlton | .050″ | 3/8″ |

| A2 | Carlton | .058″ | 3/8″ |

| A3 | Carlton | .063″ | 3/8″ |

| B1 | Carlton | .050″ | .404″ |

| K2 | Carlton | .058″ | .325″ |

| K3 | Carlton | .063″ | .325″ |

| H21 | Husqvarna | .058″ | .325″ |

| H22 | Husqvarna | .050″ | .325″ |

| H23 | Husqvarna | .050″ | .325″ |

| H25 | Husqvarna | .058″ | .325″ |

| 27 | Oregon | .063″ | .404″ |

| 28 | Oregon | .050″ | .404″ |

| 33 | Oregon | .050″ | .325″ |

| 34 | Oregon | .058″ | .325″ |

As you can see, each manufacturer has a different character and number combination markings. Oregon uses only numbers and no characters.

Stihl uses 3 marking on their chains, as can be seen in these examples:

| Marking On Drive Link | Marking On Tooth Link | Brand | Gauge | Pitch |

| 1 | 1 | Stihl | .043″ | 1/4″ |

| 1 | 3 | Stihl | .050″ | 1/4″ |

| 3 | 2 | Stihl | .050″ | .325″ |

| 5 | 2 | Stihl | .058″ | .325″ |

| 6 | 2 | Stihl | .063″ | .325″ |

| 3 | 3 | Stihl | .050″ | 3/8″ |

What Do Numbers On A Chainsaw Chain Mean?

The numbers on a chainsaw chain are for the pitch and gauge measurements. These are what determine whether the chain will fit a certain chainsaw. Each manufacturer will have their own unique ID code for their chains.

Chainsaw Chain Sharpening – Is it Difficult?

Sharpening a chainsaw requires certain tools and skills, but it is not difficult. This can be done using the proper file size, a grinder, and a bit of time.

When sharpening a chainsaw, the teeth on the chain are grinded down evenly, the leading angle of the tooth is ground away until a fresh new cutting edge is created. Bent teeth are straightened so they cut effectively.

How Many Times Can A Chainsaw Chain Be Sharpened?

Chainsaw chains can be sharpened many times, but there is a limit.

A chainsaw chain can be sharpened 3-5 times before it needs to be replaced. If the metal gets worn down enough, there will not be any left to sharpen.

There are small safety lines on the chain indicating how far it can be sharpened. The chain should not be sharpened past these or it could lead to the chain failing and causing serious injury.

Chainsaw Chain Pitch – Is It Important?

Chainsaw chain pitch is the distance between one rivet on a drive link (on a standard saw chain) to the next. A chainsaw with a 3/8 pitch chains will have an approximate distance of 3/8 of an inch between each rivet.

Pitch is usually measured in inches and displayed as either a fraction or decimal (.325″, .404″, etc.).

A person can determine the pitch themselves by counting the distance between 3 consecutive rivets on the chain and divide this number by two. Fortunately, chainsaw manufacturers calculate this already and display this on the saw or in the user’s manual.

Generally, a larger pitch size means the chain is bigger and heavier.

It is important to know that the pitch of the chain, the pitch of the bar tip, and the pitch of the drive sprocket must all match for the saw to work well.

Pitch Size Most Used By Chainsaw Professionals

3/8″, or .375″ is the pitch size most used by professionals in logging and forestry operations throughout North America. 3/8″ runs at good cutting speed with low weight on professional high RPM chainsaws.

What Chainsaw Chain Stays Sharp The Longest?

Higher quality chains, from reputable manufacturers like Stihl and Oregon will stay sharp the longest.

Carbide tipped chainsaw chains tend to last longer than all-metal chains. Carbide makes the tips much harder and more brittle, which keeps them sharp. In fact, a carbide chain can last 2-3 times longer than a normal chainsaw chain.

They will also require less sharpening, however they are more expensive to sharpen.

Alloy Chainsaw Chains – What Are They Made Of?

Chainsaw chains are usually made of zinc or steel alloy. These can also be tipped in carbide, chrome, or even diamond for added strength.

Tips for Buying Chainsaw Chains

It may be tempting to buy the most expensive chainsaw chain, but this does not necessarily mean it will cut the best or last the longest. It is very important to buy only chains that will fit the type of guide bar and chainsaw you are using.

Each chainsaw chain is made for a certain type of cutting and may require professional skills to use it. Homeowners and others that only occasionally need to use a chainsaw should consult a local chainsaw shop for any assistance as to which chain to buy.