No one likes getting burned by molten hot metal – least of all welders. But when you’ve got a job to do, you’ve got to make do with what you’ve got. That’s why it’s important to know when to replace your welding gloves.

When your welding gloves show signs of wear and tear

Welding gloves are an important part of your Personal Protective Equipment (PPE). They protect your hands from heat, sparks, spatter, and electric shock. But like all PPE, they have a limited lifespan. Here are some signs that it might be time to replace your welding gloves:

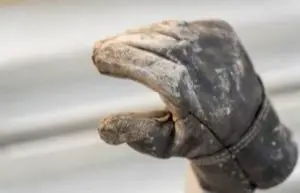

- The fabric is frayed or torn.

- The suede is worn through in spots.

- The seams are coming apart.

- The cuffs are frayed or torn.

- The palm is worn through in spots.

- There are holes in the fingers or thumb.

If you see any of these signs, it’s time to replace your gloves. It’s also a good idea to keep a spare pair on hand so you’re never caught without proper PPE.

If you feel like your gloves are no longer providing adequate protection

If you feel like your gloves are no longer providing adequate protection, it’s probably time to replace them. Depending on how often you use your gloves, they may only last a few months or a few years. Here are a few things to look for that indicate it’s time for new gloves:

- The fabric is worn thin or has holes in it.

- The palm is cracked or splitting.

- The fingers are misshapen.

- The thumb is especially worn.

- The wrist strap is frayed or broken.

When you start to experience discomfort or pain while wearing your gloves

If you start to experience discomfort or pain while wearing your gloves, it’s time to replace them. Other signs that it’s time for new gloves include:

- Fraying or holes in the fabric.

- Worn-out palm padding.

- Fingers that are too long or too short.

If you regularly use your gloves for welding, it’s a good idea to keep a few pairs on hand so you can rotate them. This will help extend the life of your gloves.

If you notice any holes or tears in your gloves

If you notice any holes or tears in your gloves, it is time to replace them. Do not try to repair the gloves yourself, as this will decrease their effectiveness and could cause further injury. Make sure to dispose of your old gloves properly, as they may still contain hazardous materials.

If your gloves become stiff or inflexible

If your gloves become stiff or inflexible and no longer provide the dexterity you need, it’s time to replace them. This usually happens long before the fabric or stitching wears out. Worn-out gloves are more than just a nuisance-they can be dangerous.

If you can’t grip the welding torch or workpiece properly, you’re more likely to have an accident. And if your gloves aren’t providing adequate protection from the heat, you could get serious burns.

If the palm or fingers of your gloves start to show signs of wear

It’s time to replace your welding gloves when the palm or fingers of your gloves start to show signs of wear. If you see any holes, rips, or fraying, it’s time to get a new pair of gloves. Worn gloves can cause burns, blisters, and other injuries. If you’re not sure if your gloves are still safe to use, err on the side of caution and get a new pair. It’s better to be safe than sorry!

If the tips of your gloves start to show signs of wear

If the tips of your gloves start to show signs of wear, it’s time to replace them. Here are some other signs that your gloves need to be replaced:

- The cuffs are frayed

- The palms are worn

- There are holes in the fabric

- The seams are coming undone

If you have any other concerns about the condition of your gloves

If you have any other concerns about the condition of your gloves, it is always best to consult with a welding supply professional or glove manufacturer. They will be able to help you determine if your gloves need to be replaced and if so, can offer suggestions on the best options for you and your welding needs.

In Closing

Remember, welding gloves do not last forever. If you can see through them, or they have worn tips or bad seams, it’s time for a new pair. It is better to be safe than sorry!