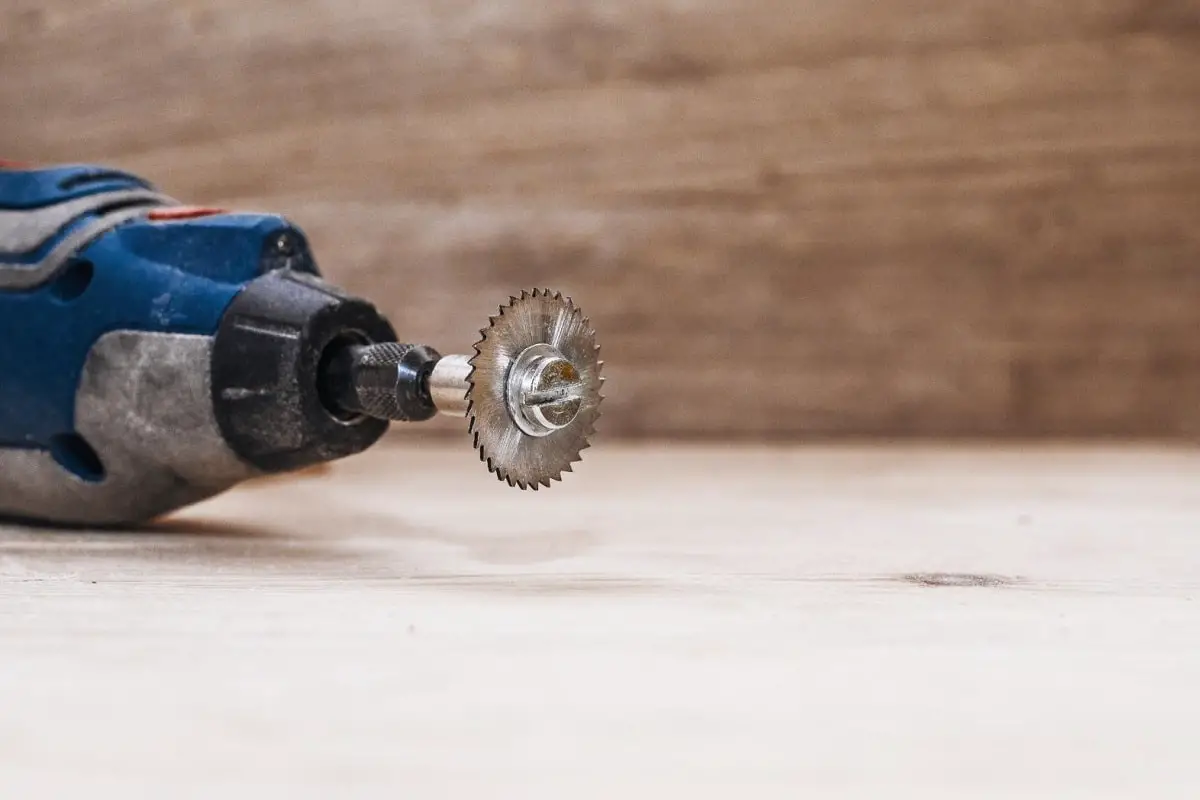

The dremel is an important tool that every craftsman should have. If you are not careful, however, the Dremel will start to accumulate dust which can impair its function. Also, fluid will get inside your Dremel and also cause it to malfunction. Here are some tips on how to inspect your Dremel and clean it when needed.

Dremel Parts

A dremel is made up of a number of parts, which include:

- Motor

- Brushes

- Driveshaft

- Cord

- 2 piece casing

- Chuck / rotary shank

- Battery

- Bits / attachments

- Driver cap

- Collet nut

- Nose cap

The dremel motor consists of a complete motor, spindle lockout sprocket, spindle bearing, and driveshaft. A motor can burn out, especially if covered in dust and with too much pressure applied while cutting. This can cause it to fail, either permanently or temporarily.

The motor lockout sprockout can be worn away, the motor bearings can jam, or the threads on the collet taper can be damaged. When this happens, the motor may need to be replaced, which the user can do themselves using small hand tools.

If the power cord becomes damaged, such as being cut or cracked and the internal wiring is exposed, it can be replaced. This requires opening up the dremel and removing the two screws that hold the power cord to the body. Another power cord can then be attached by replacing the screws and closing the body

A big problem with many Dremel motors is a wire connected to the coil breaks. This requires pulling out the clip and unwrapping wire from the coil to extend it to the clip.

Another problem with Dremel motors is the clips that hold the wire get loose and do not connect properly. This requires a readjustment of the clips so they make contact with the motor pins.

A dremel is desinged to be easily maintained by the user, which is one reason it is such a handy tool. However, if it is used often, it will be more prone to failure.

Inspecting A Dremel

Inspecting a dremel is quite easy.

Look at the tip for any cracks or chipped metal. If the bit is worn down or clogged, consider replacing it.

Visually inspect the air intake / exhaust areas. Clear these of any built up dust particles so the air flow is not blocked.

Check the cord where it connects to the dremel body. If it is split and the internal wires are exposed, consider replacing the dremel or use electrical tape to repair it.

Cleaning A Dremel

To clean the inside of a dremel, it needs to be taken apart:

- Remove the motor brushes.

- Remove the torque screws holding the Dremel together.

- Remove the end clip, and take apart the two halves.

- Look at the inside.

- Clean out the dust you see.

The switch contact surface is a point of most problems with dremels. This can make the Dremel stay turned on. Clean the contacts of any dust using a q-tip and rubbing alchohol.

Place the lock pin back in the slot and put the spring clip back in the top of it. Put the 2 peices of the dremel together and screw in the torque screws.

Most dremel parts can be easily cleaned using a cloth or rag and some rubbing alchohol or degreaser. The parts that are most susceptible to grime and dust are the motor, brushes and bits. Fortunately, a dremel is easy to inspect and take apart to clean.

Dremel Storage

It is important to store your dremel properly. This can help prevent any damage do it, or cause it to malfunction when you need it.

Storing A Dremel

Storing a dremel in a locked space will help prevent if from being stolen, or used by a child without your permission.

Store your dremel in a closet, cupboard, garage work bench, or a toobox.

Very hot or very cold temperatures may damage certain components, such as the cord or battery. So store the dremel in a place that avoids direct sunlight, rain, or ice.

Ways to store a dremel include:

- Plastic Ziplock bag

- Plastic case

- Wood case / box

- Cabinet

- Closet

- In a vehicle trunk

You can purchase a case for a dremel online that fits the version you own.

Dremel Case

Dust, dirt particles, fluids, chemicals, can damage a dremel rotary tool. This is why having a waterproof and dustproof storage case is important.

Dremel cases can fit large and small dremels, and they usually have carry handles for easy mobility. Along with the dremel, they will have space for bits, power cords, batteries, and a wrench.

In Closing

Inspecting and cleaning a dremel does not have to be too much of a chore. Being such a small device, it is easy to take apart and put together for most users. However, even while doing so, keep safety in mind, and especially watch out for the power supply and sharp cutting tips.