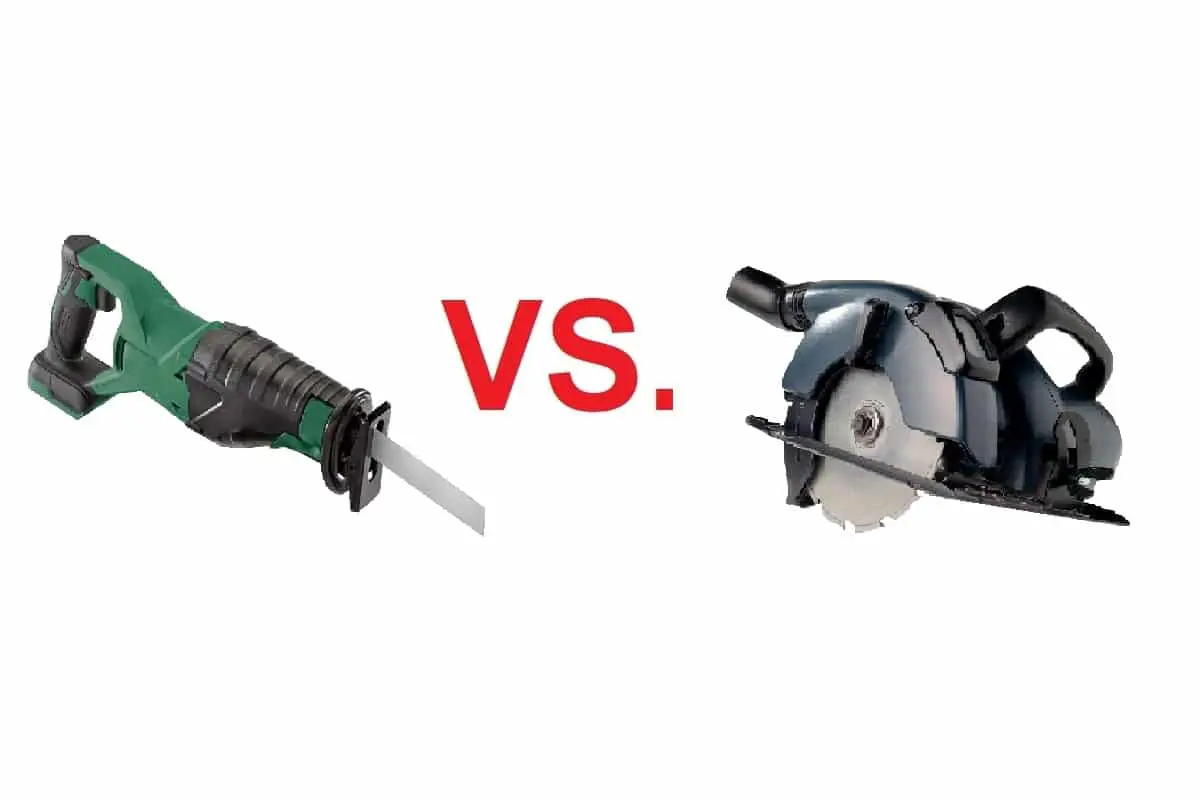

Both reciprocating saws and circular saws are powerful and effective cutting tools. They each make doing construction jobs faster and easier. But which one is better? Find out in this post.

Reciprocating Saw Strengths

- Battery or cord powered

- Flexible, mobile, and rugged

- Quick and easy blade changes

- Water and dust-resistant

- Vibration reduction mechanism

- Low risk of overheating and overloading

- Has a wide variety of blades for cutting different materials

- Variable-speed trigger

Most reciprocating saws are not completely water-proof. However, the Nemo Power Tools submersible reciprocating saw is waterproof and will operate underwater at depths up to 50m (164ft).

Circular Saw Strengths

- Battery or cord powered

- Quickly cuts wood boards and plants

- Cuts in a straight line

- Easy to store and carry

- Dust port included to minimize dust during cutting

- Blade runs at very high speeds (4000+ RPMs)

- Uses different blades for cutting different materials

Which Is Better, A Circular Saw Or A Reciprocating Saw?

This depends on the cutting task. Each saw has its own unique strengths and weaknesses based on the shape and motion of the blade. For cutting straight lines through boards and plants, a circular saw may be best. For semi-straight cuts in tight spaces, a reciprocating saw is better.

If you think you will need to cut a wide variety of materials in a different locations, having both types of saws may serve you well.

Reciprocating Saw Length

Reciprocating saws are not very long. There are two components to consider when considering length: the length of the blade, and the length of the body of the saw.

Reciprocating Saw Dimensions

Dimensions of reciprocating saws are generally:

Length – 13 – 17 inches

Height – 4 – 5 inches

Width – 3 – 4 inches

Weight – 6 – 7 pounds

Reciprocating Saw Blades

There is a wide variety of reciprocating saw blades to choose from, each made for different cutting purposes. Specialized reciprocating saw blades also exist for more rare cutting applications.

Reciprocating saw blade materials include:

- High-Carbon Steel

- High-Speed Steel

- Bi-metal

Additionally, many high quality blades will have non-stick coating to minimize gumming and friction. Some blades are advertised as being “carbide”, meaning they have an additional carbide plus metal compound layered as a coating.

Types of reciprocating saw blades include:

- Wood

- Metal

- Concrete – abrasive

- Pruning

- General purpose

Reciprocating Saw Blade Length

Reciprocating saw blades come in various lengths. These include:

- 6″ x 5/8″, 3/4″, or 1″

- 9″

- 12″

Different sized blades are made for cutting different sized and shaped materials. Blades are universal, meaning they will fit in any reciprocating saw with a 1/2″ universal shank.

Reciprocating Saw Teeth

The reciprocating saw blade teeth do most of the work during cutting. Different sized teeth match the type of material they are shaped to cut.

A reciprocating saw’s teeth count is measured in teeth per inch (TPI). This ranges from 2 to 24 TPI, with the higher the number equating with a smoother cut.

More rugged blades will make rough cuts and have a lower TPI number. For example, blades made for cutting wood will have less teeth than those made for cutting metal.

Reciprocating Saw Weight

Reciprocating saws weigh between 6 – 7 pounds.

Can You Cut 2×4 With Reciprocating Saw?

Yes. A reciprocating saw can easily cut through a 2 x 4 using a wood cutting blade.

Can You Cut Plywood With A Reciprocating Saw?

Yes, plywood can be cut by a reciprocating saw using a wood cutting or general purpose blade.

Can You Cut A Tree With A Reciprocating Saw

Yes, you can. However, the length of the blade is limited, so the diameter of the trunk or branches must not be too big.

In fact, reciprocating saws are excellent for cutting up fallen branches for stacking or removal. However, if the wood is too fibrous or wet, it could cause the blades to get gummed up by wood fibers and dust.

How Thick Of A Branch Can A Reciprocating Saw

Cut?

A reciprocating saw can cut a branch or tree trunk of up to 8 inches in diameter. The size of the tree you can cut is limited to the length of the blade and power of the motor.

You can make multiple cuts and ‘chisel’ the tree branch or trunk which means the branch can be larger than x inches.

Reciprocating saws are not the ideal saw for cutting down trees. This role would usually go to the chainsaw. However, they are good for cutting or pruning smaller trees.

Special blades made for pruning wood can be purchased that have a TPI (teeth per inch) between 2-6. Using a strong blade, such as bi-metal or carbon steel, will probably be best.

What Materials Can Be Cut With A Reciprocating Saw?

Materials that a reciprocating saw can cut include:

- Wood (trees, bushes, boards, planks)

- Metal (sheets, bolts, wiring, thin rebar, steel, aluminum, copper, and cast iron pipes)

- Concrete

- Stone and tile

- Plastic and rubber (foam, pvc pipes, etc.)

Can You Cut PVC With A Reciprocating Saw?

Yes, you can cut PVC with a reciprocating saw using a wood, metal, or general purpose blade.

Reciprocating Saw Speed

Reciprocating saws run quite fast. The blade moves back and forth quickly to cut through materials in very little time.

The actual speed of the blade is determined by three factors: the speed of the reciprocating motion, the blade length and the number of teeth on it.

Reciprocating saws have a speed range from 0 to 3000 strokes per minute (SPM). The longer the blade length, the less SPM it will have. Also, the less teeth the blade has (TPI), the slower it will move back and forth.

Additionally, variable speed reciprocating saws have triggers that allow for gently squeezing to produce the speed desired.

To Recap…

Both reciprocating saws and circular saws are very effective at what they are designed for. Regardless of which one you choose to use, always wear proper safety gear and keep safety in mind to prevent injuries to yourself or others.