In this article we discuss the working conditions where arc flash suits are required. We also discuss the dangers of arc flashes and the required standards for arc flash suits to protect you from them.

If you are looking to buy an arc flash suit check out our useful Arc Flash Suit Buying Guide.

When Arc Flash Suits Are Required

Arc flash suits are personal protective equipment (PPE) worn by electricians working with highly electrified power sources or equipment.

Arc flash suits are required wherever there is potential for a high-power electrical arc. These typically occur in and around power lines, switches, generators, storage facilities and other electrical equipment.

Conditions Requiring Arc Flash Suits

Arc flashes and explosions can be caused by:

- Failed or damaged insulation

- Tools bridging the gap

- Rodent or bird nests

- Tree branch or root damage

- Structural failure

- Lightning strike

- Wind damage

- Failure to de-energize the components before work begins (i.e. human error)

- Any activity described in NFPA 70E Table 130.5(C) Estimate of the Likelihood of Occurrence of an Arc Flash Incident

Whenever these types of conditions might exist, an arc flash suit with the correct rating is required.

Voltage and Electrical Energy Thresholds

The voltage of the connections is an important element in whether an arc flash suit is required. Dangerous arc flashes start occurring at about 120 volts, and escalate quickly in power and danger as voltage increases.

Dangerous second-degree arc flash burns begin to occur at around 1.2 calories per centimeter squared per second (5 joules per centimeter squared per second). This is roughly equivalent to holding a finger over a cigarette lighter for one second.

According to the National Fire Protection Association (NFPA) NFPA 70E standard for arc flash protection, arc-rated protective clothing is required whenever there is possible exposure to an electric arc flash above the 1.2 calories per centimeter squared per second threshold. NFPA 70E applies to shock, electrocution, arc flash, and arc blast. OSHA workplace safety regulations also reference NFPA 70E.

Above these voltage and energy levels, wearing an arc flash suit is mandatory.

Arc Flash Boundary Distances

Another factor is the distance from the source of the arc flash. Different arc flashes have different boundaries, within which workers must wear arc flash protective gear. Ouside of these boundaries a reduced level of protection is required, or even none.

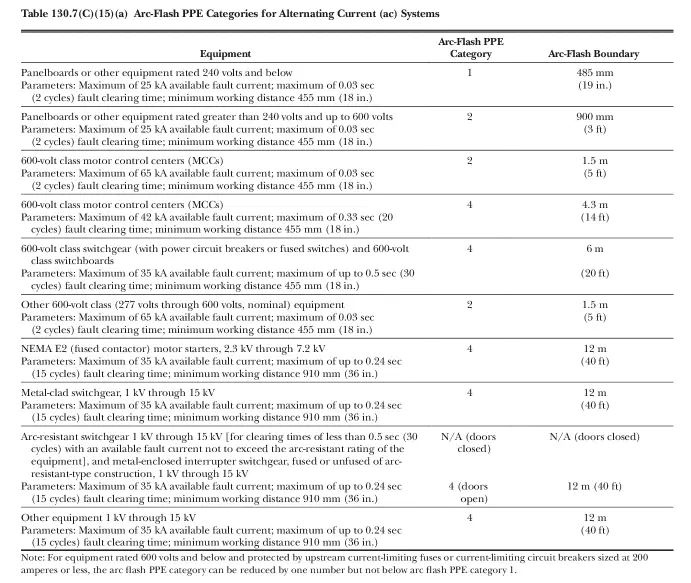

To determine the arc flash boundary distance in the working environment, refer to Table 130.4(D)(a) in the NFPA 70E standards.

How Dangerous Are Arc Flashes?

An arc flash is an electrical current that passes through the air when the space or insulation around two conductors fails to contain the voltage. Arc flashes (and accompanying explosions) can expel incredibly huge quantities of heat energy due to the ionization of air. This can result in temperatures up to 36,000 degrees Farenheit.

If the voltage is high enough when an arc flash occurs the electrical conductors can become hyper-heated and vaporize. Vaporization of copper, for example, causes it to expand by a factor of 67,000 instantly(a). This vaporization shoots tiny bits of molten metal and plasma through the air at extreme velocity. It also creates a powerful blast with potentially deadly force of 2000 psi or greater.

An arc flash also generates intense light waves ranging in spectrum from infrared to ultraviolet. The human body and other objects absorb this light and turn it into heat instantly. This can cause super-heating of the skin and clothing, further contributing to burns beyond the heat generated by air ionization.

Naturally, anybody close to the flash can suffer life-threatening burns if he or she is not protected with appropriate gear. Burns can happen to anybody within 10 feet of the arc flash. If the flash is accompanied by a large blast, workers and bystanders can be thrown and suffer impact injuries similar to a small bomb.

Arc Flash Suit Protection Levels

An arc flash suit must meet the arc-flash PPE category levels for the conditions it is used in. These conditions and categories are laid out in NFPA 70E Table 130.7(C)(15)(a) below:

You can read more about NFPA ratings and protection levels in our Arc Flash Ratings Guide here.

Arc Flash Suit Design & Performance Requirements

Arc flash suits are made to meet varying levels of performance and safety standards, measured in calorie/per cm2. For example, a pant plus jacket overall of 15CAL would offer protection against heat energy of less than 15cal/cm2 produced by arc flashes.

For the complete documentation on arc flash suit design, manufacturing and performance requirements see ASTM International’s site at http://www.astm.org/cgi-bin/resolver.cgi?F1506

ASTM’s standards describe the minimum performance requirements for arc flash suits, including the:

- Arc rating of fabrics

- Flame resistance of fabrics and subassemblies

- Mechanical durability of the fabrics and subassemblies

- Minimum garment construction and performance requirements

- Garment labeling requirements

Who Should Wear Arc Flash Suits?

Generally anybody who is working within 10 feet of an electrical connection above 120 volts should wear arc flash personal protective equipment.

This includes:

- Electrical linemen

- Electrical line and station inspectors

- Foremen

- Field Engineers

- Anybody else who is regularly within 15 feet of a high-voltage electrical installation or repair site

Highly Rated Arc Flash Suits

Oberon Company – HRC2-CKE-NB-XL 8 Cal HRC2 Series Arc Flash Kit, Navy Blue

National Safety Apparel KIT2CV113X08 ArcGuard CAT 2 Arc Flash Kit with FR Coverall

References

- https://www.ishn.com/articles/97409-all-about-arc-flash-definitions-dangers-stats-causes-and-prevention

- https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=70E

- https://en.wikipedia.org/wiki/Arc_flash

- (a) Electrical Safety in the Workplace, Ray A. Jones, Jane G. Jones, National Fire Protection Agency, 2000, Page 32

- http://www.astm.org/cgi-bin/resolver.cgi?F1506